What Distinguishes an Industrial PC from a Standard PC?

- Rohit Sharma

- Apr 24

- 6 min read

When you think of a personal computer (PC), you likely imagine a sleek device on a desk, complete with a monitor, keyboard, and mouse. It’s designed for general purposes—gaming, productivity, entertainment, and more. However, there’s another class of computers that differs significantly from traditional PCs: Industrial PCs. These industrial panel PC are engineered for use in harsh environments and demanding industrial applications, where reliability, durability, and functionality are paramount. But what exactly distinguishes a PC from an industrial PC? Let’s dive into the specifics.

What is an Industrial PC?

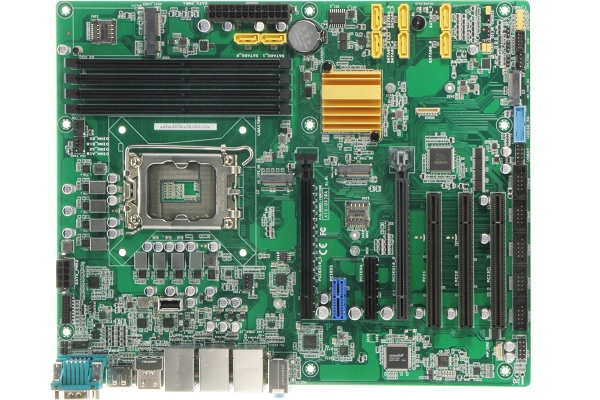

An Industrial PC (IPC) is a type of computer designed specifically for use in industrial environments, where reliability, durability, and performance are critical. These computers are built to withstand harsh conditions such as extreme temperatures, dust, vibration, and moisture. Industrial PCs are commonly used in manufacturing, automation, and other industries that require real-time data processing and control. Unlike regular consumer PCs, IPCs are built with rugged components and are often used for tasks like machine control, process monitoring, and equipment management, making them essential for the smooth operation of industrial systems.

Key Differences Between a Standard PC and an Industrial PC

1. Purpose and Design

Personal computers (PCs) are designed with flexibility and versatility in mind, suited for tasks like office work, multimedia consumption, gaming, and browsing. A traditional PC generally operates in comfortable, controlled environments, such as homes or offices, and can be easily upgraded or replaced as technology advances.

In contrast, industrial PCs are built for specific applications in industries like manufacturing, automotive, logistics, automation solutions, and healthcare. They are designed to operate in extreme conditions—such as high temperatures, dust, moisture, vibration, and electrical interference—conditions that would easily render a standard PC unusable.

For example, an industrial panel PC is typically enclosed in a rugged casing to protect it from physical damage and environmental hazards. The panel mount monitor is often integrated with the PC, offering a compact, user-friendly interface that is durable enough to withstand the wear and tear of industrial environments.

2. Durability and Build Quality

One of the primary distinguishing factors between a PC and an industrial PC is their build quality. Industrial PCs are constructed with superior durability and are designed to operate for extended periods in rough conditions. Unlike standard PCs, which are often made with plastic exteriors and delicate components, industrial PCs feature rugged housings made from metal alloys or heavy-duty plastic. This construction ensures that they can endure the challenges of industrial settings.

In addition to rugged construction, industrial panel computer are often sealed to prevent dust, dirt, and moisture from infiltrating the internal components. These PCs are rated with ingress protection (IP) scores, such as IP65 or IP67, indicating their level of protection against dust and water. Meanwhile, a standard PC would not be able to function properly in such environments due to its vulnerability to these elements.

A standard PC can overheat in hot environments, while Advantech products typically include cooling systems capable of maintaining optimal temperatures even in extreme heat. This is critical when working in industries like manufacturing or warehouse settings where heat and air conditioning may not be consistent.

3. Environmental Resistance

Industrial PCs are designed to withstand tough environmental factors like extreme temperatures, humidity, and vibration. Many industrial panel computers can operate in a much wider temperature range compared to standard PCs, which generally work well only within a comfortable 10-30°C (50-86°F) range. Industrial PCs, however, can function in temperatures as low as -20°C (-4°F) and as high as 60°C (140°F), making them suitable for outdoor, high-heat, or freezing cold environments.

Moreover, industries like manufacturing or construction often involve environments where vibration is constant. A panel mount monitor or industrial panel PC is built with vibration-resistant components and stabilization features, ensuring that the computer stays operational even in conditions where a regular PC might crash or malfunction.

4. Customizability and Integration

While a standard PC is generally pre-configured and cannot be easily customized for specialized applications, industrial PCs are designed with integration and customization in mind. Industrial panel computers often allow for tailored solutions, such as specific software installations, hardware configurations, or even specific touchscreens that are optimized for specific industrial monitor tasks. For instance, a panel mount monitor can be customized to have touch-screen functionality, making it easier for users to interact with the machine in an industrial setting.

Another feature that sets industrial PCs apart is the wide array of available I/O ports and expansion options. Industrial panel PCs typically offer various serial ports (RS232, RS485), Ethernet, and USB connections, which are crucial for industrial automation systems, SCADA (Supervisory Control and Data Acquisition), and other specialized applications. These ports allow for direct integration with machinery, sensors, and industrial control systems. In contrast, regular PCs may not offer the same level of adaptability for these specialized industrial purposes.

5. Performance and Reliability

Industrial PCs are designed to run 24/7 without the risk of failure, offering high levels of reliability and stability. In critical industries, any downtime is costly, so industrial panel computers are engineered for continuous operation. These systems use enterprise-grade components that can withstand continuous use, and their design focuses on minimizing failure rates.

On the other hand, PCs are often built for average usage and aren’t intended to run nonstop under extreme conditions. Although a PC can be highly powerful and efficient for standard tasks, it’s not built to operate reliably in demanding or mission-critical environments.

An all in one PC touch screen often used in Advantech industrial PC provides a great example of performance and reliability in industrial settings. These systems are built for demanding applications and offer high-resolution touch displays that can handle intensive tasks like data entry or system monitoring, which are essential in industries like logistics, automotive, and factory settings.

6. Maintenance and Longevity

The design of industrial PCs also focuses on longevity and ease of maintenance. For instance, many industrial panel PCs are modular, allowing for individual components to be replaced without the need to discard the entire system. This reduces the total cost of ownership and extends the lifespan of the equipment.

In contrast, a standard PC may have limited upgrade options, and repairs often require replacing the whole unit if something goes wrong. Additionally, the parts in industrial PCs are designed to last longer and handle heavy workloads, further justifying their higher initial investment.

7. Specific Applications in Industrial Environments

Industrial panel PCs are compact, all-in-one systems that integrate a computer and touch screen into a single device, providing both functionality and space efficiency. They are designed for easy installation and mounting on walls or control panels, making them ideal for environments where space is limited, such as factory floors, warehouses, or control rooms. With their rugged build quality, these panel PCs are built to withstand the harsh conditions of industrial settings, including exposure to dust, moisture, extreme temperatures, and vibration. They offer reliable performance, ensuring real-time data processing and control for tasks like monitoring production lines, controlling machinery, and managing automation systems, all while providing an intuitive and user-friendly interface for operators.

Conclusion

The primary difference between a standard PC and an industrial PC lies in the design, build quality, environmental resistance, and customizability of the devices. While personal computers are designed for general tasks like office work, entertainment, and browsing, industrial PCs are built to withstand harsh conditions and provide continuous, reliable performance in demanding environments. Industrial PCs, such as industrial panel computers, panel mount monitors, and all-in-one PC touch screens, are designed to integrate seamlessly into industrial settings. These systems are capable of withstanding extreme temperatures, moisture, dust, vibration, and other challenging factors, making them ideal for industries such as manufacturing, logistics, healthcare, and automation. Additionally, industrial PCs offer specialized I/O ports and customizability for specific industrial tasks, providing a level of adaptability that standard PCs simply cannot match.

For businesses seeking industrial PC solutions, companies like ITG India offer advanced technology with robust designs tailored to the needs of demanding industries. ITG India provides a wide range of industrial automation solutions, ensuring that companies can access reliable, durable systems that are built to perform in even the toughest environments. When you need a system that offers continuous performance, customization, and environmental resistance, industrial PCs are the ideal choice. ITGIndia’s trusted solutions are designed to keep operations running smoothly, supporting critical tasks with technology that lasts and delivers consistent results.

Reference Link: https://www.itgindia.com/blogs/what-distinguishes-an-industrial-pc-from-a-standard-pc/

Comments