Best Practices for Using Rugged Tablets in Tough Conditions

- Rohit Sharma

- Jul 23

- 4 min read

In industrial and field environments where heat, dust, moisture, and vibration are daily realities, consumer-grade devices simply don’t hold up. That’s where rugged tablets come into play. Built to endure the harshest of conditions, rugged tablets are designed to maintain performance and durability in sectors like manufacturing, logistics, defense, oil & gas, construction, and more.

This article explores the best practices for using rugged tablets in tough conditions, helping businesses get the most out of their investment. We’ll also highlight related technologies like industrial tablets, panel PCs from Advantech, industrial panel computers, industrial monitors, and industrial single board computers that work alongside or in support of rugged tablets in the modern industrial ecosystem.

What Are Rugged Tablets?

Rugged tablets are computing devices built to withstand extreme environments. Unlike standard consumer tablets, they are certified with standards such as IP65/IP67 (protection against dust and water) and MIL-STD-810G (resistance to shock, vibration, and temperature extremes).

Rugged tablets are frequently used in field service, warehousing, military operations, outdoor inspections, and manufacturing facilities across India and worldwide.

Why Use Rugged Tablets?

Before jumping into best practices, it’s important to understand why rugged tablets are the preferred choice in challenging environments:

Durability: With reinforced exteriors, rubberized edges, and impact-resistant screens, rugged tablets can survive drops, spills, and exposure to chemicals.

Extended battery life: Ideal for long shifts or remote work.

High-brightness displays: Usable in direct sunlight or dim industrial settings.

Comprehensive connectivity: Includes multiple USB ports, RS-232, LAN, Wi-Fi, and LTE for seamless data transfer.

Customizability: Support for barcode scanners, RFID, and GPS modules, depending on application.

Best Practices for Using Rugged Tablets in Tough Conditions

1. Choose the Right Rugged Tablet for Your Environment

Different industries have different operational demands. For example, oil & gas may require ATEX-certified devices for explosion-proof performance, while logistics firms may prioritize RFID scanning and LTE connectivity.

Tip: Consider additional accessories like vehicle mounts, hand straps, and docking stations. Brands offering industrial tablets often provide these as optional add-ons.

2. Regularly Inspect and Maintain Devices

Even the toughest devices can degrade over time if neglected. Implement regular inspection schedules to check for:

Damaged ports

Cracked screen

Battery health

Loose screws or covers

Pro tip: Use screen protectors and port covers to prolong the life of your rugged tablets.

3. Use Industry-Compatible Operating Systems and Software

Rugged tablets often run on Windows or Android. Choose the OS and software that aligns with your existing infrastructure.

For example, manufacturing setups that use industrial panel computers or panel PC Advantech systems running Windows may benefit from rugged tablets that support seamless integration with the same platform.

4. Optimize for Network and Data Security

In harsh and remote conditions, secure and stable connectivity can be a challenge. Make sure your rugged tablet is:

Equipped with VPN for secure remote access

Protected with mobile device management (MDM) software

Updated regularly with firmware patches

For businesses working alongside industrial single board computers and industrial monitors, security should be consistent across all connected devices to prevent vulnerabilities in an otherwise robust infrastructure.

5. Train Your Workforce

Technology is only as effective as its users. Conduct regular training to ensure your team knows how to:

Handle rugged tablets properly

Perform software updates

Use specialized features like barcode scanners or GIS tools

Troubleshoot basic connectivity or performance issues

This becomes especially important in environments where panel PCs or industrial monitors are fixed and tablets are used to extend operational mobility.

6. Store and Charge Devices Correctly

In dusty, high-humidity, or high-temperature environments, proper storage can make or break device longevity. Use ventilated and secure storage lockers or charging cabinets designed for industrial tablets.

Avoid overcharging batteries or exposing tablets to direct heat when not in use.

7. Integrate with Existing Industrial Systems

A rugged tablet shouldn’t operate in isolation. It should seamlessly connect with your existing setup that may include:

Industrial panel computers for process monitoring

Panel PC Advantech units used on the factory floor

Industrial monitors displaying real-time production metrics

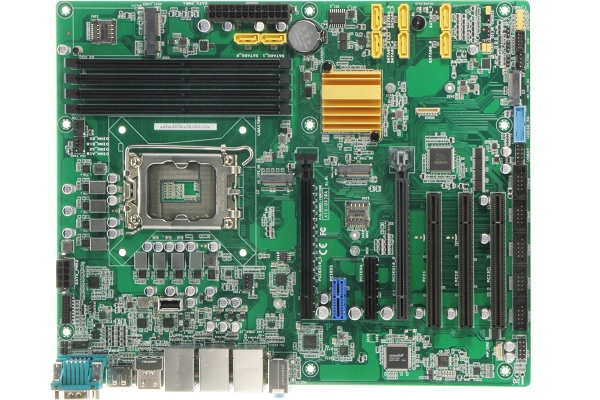

Industrial single board computers controlling machines or robotics

Use tablets to collect data, report status, and interact with backend systems in real time.

Use Cases in the Indian Industrial Landscape

India’s fast-growing industrial sector is increasingly adopting rugged computing technologies. Here’s how rugged tablets and related systems are used:

Manufacturing

Workers use rugged tablets to perform equipment checks, log maintenance tasks, and monitor live data transmitted from industrial single board computers.

Smart Warehousing

Warehouse personnel use industrial tablets to scan inventory, update stock records, and communicate with central systems managed by panel PCs.

Agriculture & Mining

Field workers in remote areas use GPS-enabled rugged tablets to track resources and update central servers via 4G, linking with industrial monitors back at control centers.

Government & Public Services

Utilities departments use rugged tablets for infrastructure inspection and reporting, integrating with industrial panel computers that manage SCADA systems.

Final Thoughts

As Indian industries move toward smarter and more connected operations, rugged tablets play a vital role in extending mobility, ensuring reliability, and improving efficiency—even in the harshest conditions.

To maximize their value, follow best practices for use, integrate them with other industrial computing systems, and keep your workforce trained and supported.

Whether you’re building a smart factory, managing remote infrastructure, or upgrading field operations, rugged tablets, along with panel PC Advantech, industrial panel computers, industrial monitors, and industrial single board computers, provide the robust foundation your business needs to thrive in tough environments.

Comments